Tøv ikke med at sende en besked

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. (Tidligere Hengtai Motor) Etableret i 1995 og tidligere kendt som "Hengtai Motor" (det kinesiske navn på vores virksomhed), antog vi officielt det engelske navn "HENTACH Motor" i 2020. Begge navne repræsenterer den samme betroede producent dedikeret til elektromekanisk innovation i over 30 år. Med speciale i støbning og præcisionsbearbejdning af miniature DC-motorer, el-/motorcykelnavmotorer og aluminium-magnesiumlegeringer til elektriske køretøjer, kombinerer vi et stringent ISO 9001 kvalitetskontrolsystem, moden ledelsespraksis og banebrydende produktions-/testudstyr for at levere pålidelige løsninger.

With end-to-end capabilities spanning from raw material casting to final product delivery, we serve diverse markets including e-bikes, cargo vehicles, AGVs, golf cars, agricultural machinery, and e-karting. Our 9,000+㎡ campus (5,000㎡ built area) houses over 60 units of advanced production equipment, including 500-ton die-casting machines, precision CNC machine tools, laser marking systems, micro-arc oxidation lines, and two dedicated electric vehicle motor test benches. This infrastructure ensures efficient production and strict compliance with international quality standards.

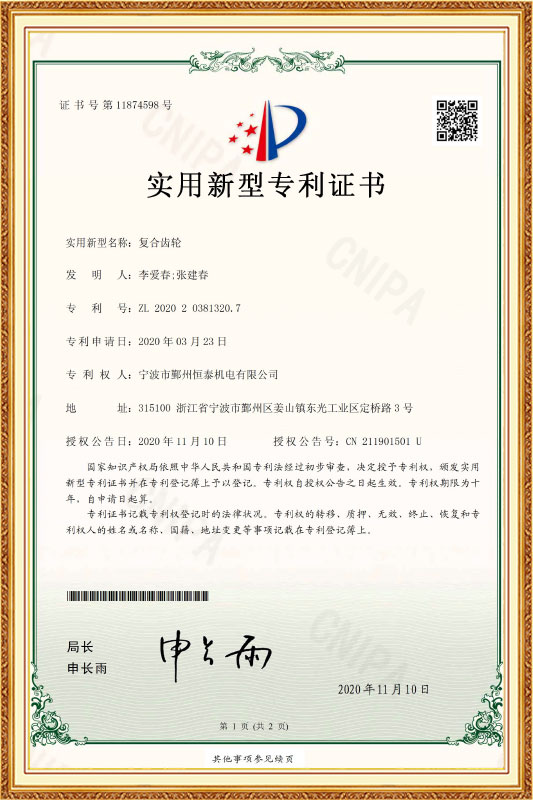

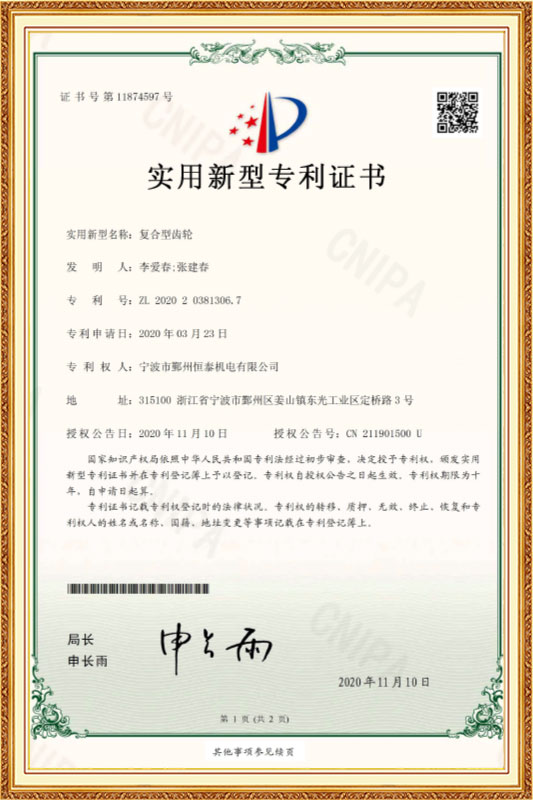

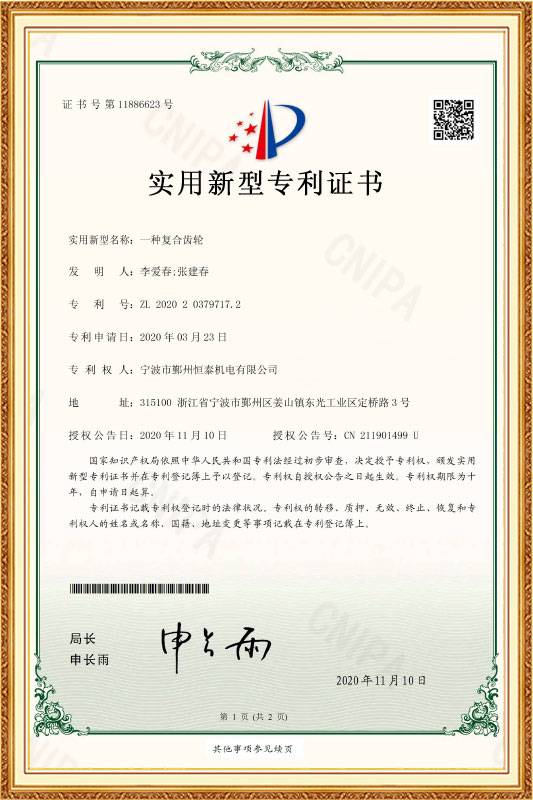

Hos HENTACH (Hengtai) prioriterer vi materialer af høj kvalitet og proprietær teknologi - vores patenterede nylon-stål gear er et bevis på vores tekniske ekspertise. For at validere holdbarheden lancerede vi engang et kilometergarantiprogram for motorer, der overstiger 30.000 miles. Resultatet? Over 50 motorer opfyldte ikke kun dette benchmark, men overgik det, hvor nogle nåede imponerende 50.000 miles. Denne præstation i den virkelige verden afspejler vores urokkelige fokus på pålidelighed og motiverer os til kontinuerligt at innovere for smartere, stærkere motoriske løsninger.

Stol på mærket, der er kendt globalt som både Hengtai Motor og HENTACH Motor - hvor patenteret stålgearinnovation møder dokumenteret holdbarhed.

High power, high torque, high adaptability: HENTACH leads the wave of technology upgrades for hub motors of electric cargo bikes

Compared with traditional electric power-assisted bicycles, electric cargo bikes have higher requirements for motor power output, torque capacity and durability. Hub motors are widely used in such vehicles due to their compact structure, convenient installation and high transmission efficiency, and have become the mainstream power solution in the field of electric freight.

This field has the characteristics of both front-wheel drive and rear-wheel drive, among which high torque output, durability and adaptability to a variety of wheel diameters and transmission systems are the mainstream trends in the industry. For example, in typical application scenarios such as urban climbing, multi-frequency start-stop, and heavy-load transportation, rated power exceeding 500W and peak torque exceeding 75-100Nm have become the performance benchmarks for hub motors of electric cargo bikes. At the same time, in order to achieve a balance between power and efficiency, more and more manufacturers are adopting outer rotor structures, electromagnetic optimization designs, supplemented by high-strength gear materials and precise control algorithms to cope with the challenges brought by high loads and long-term operation.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. is promoting the continuous evolution of electric cargo bicycle hub motor technology to meet the diverse needs of urban logistics and heavy-load riding. Its E-type, S-type, and J-type series hub motors not only cover multiple power levels from 250W to 2000W, but also provide a variety of structural solutions from front-wheel drive, rear-wheel drive to through-axle, covering various application scenarios from light-load urban freight to high-intensity mountain off-road.

HENTACH provides a variety of speed compatibility solutions for mainstream models in the market. The E-Type series supports 7-speed gearboxes and 8-10-speed gearboxes to meet the matching needs of transmission systems of different manufacturers. Models such as E-Type RF750-2 and RC750-2 can be matched with 135mm or 142mm rear wheels, which are compatible with most current freight and mountain bikes. High-end models such as S-TYPE MAX R2000 use a 12mm through-axle structure with higher rigidity, especially suitable for high-load systems of E-Fat and Moped. The peak torques of the E-Type RF500-1 and RC750-2 series are 75Nm and 85Nm respectively, and they are widely compatible with 20-28 inch wheel diameters, ensuring fast low-speed starting and strong climbing ability. To cope with more extreme load and terrain requirements, the S-TYPE F1500 and R2000 have launched 1500W and 2000W power solutions respectively, with maximum torques of up to 145Nm and 170Nm respectively, which can easily cope with extreme slopes and high-intensity freight. HENTACH's high-efficiency products such as the J-TYPE R350 ECO also show that in markets where regulations restrict power, how to improve efficiency and endurance through structural optimization is becoming another important direction. In addition to high-performance motors, HENTACH also attaches importance to energy efficiency optimization. Its light-load product J-TYPE R350 ECO motor improves the energy efficiency of the whole machine to 86% (the industry average is 81%) through structural innovation, and effectively reduces energy consumption and battery configuration costs. It is especially suitable for urban delivery or shared bicycle platforms that have high requirements for efficiency and endurance.

In short, the electric cargo bike hub motor industry is moving towards high power, high torque, lightweight, long life, and intelligent control. Enterprises need to strike a balance between performance, reliability, and diversified supporting capabilities to stand out in the fierce global market competition. HENTACH plays an important role in this wave of change with its manufacturing capabilities and innovative technology.